- Home

- >

- D-SIMCON

D-SIMCON

Unveiling the

essence of D-SIMCON

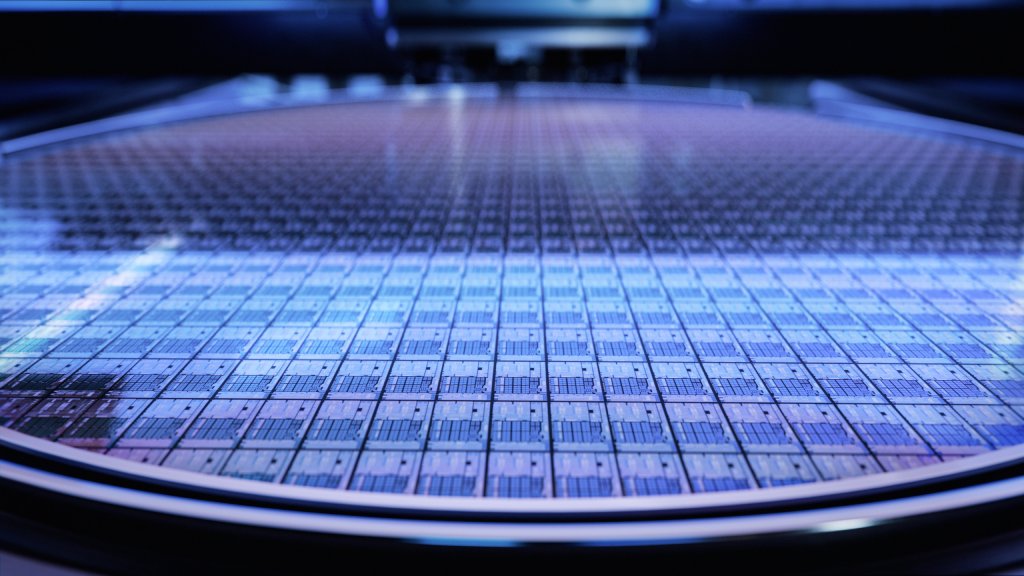

D-SIMCON is a suite of advanced domain-specific decision support modules for Capacity Planning & Optimisation, WIP Management and Scheduling & Dispatching in Semiconductor Manufacturing. The solution addresses the typical challenges in operating and managing the dynamic production line of a factory as complex as a wafer fabrication facility.

All modules can be deployed on a parallel computing infrastructure and are Cloud compliant to maximise scalability and minimise execution times.

Industry Challenges

Dynamic Business Environment

Everchanging external and internal business drivers – many of which are stochastic – call for proactive and agile planning and execution.

Complexity of Planning Parameters

Comprehensive tools for decision variable optimisation and action prioritisation in a resource-constrained production environment – with often non-intuitive interdependencies – are required.

Heterogenous Data Landscapes

Consistent and accurate data integrated from multiple sources without having to rely on simplistic assumptions is critical to decision-making.

Differentiators

Built for Semicon

Incorporating all pertinent domain-specific characteristics.

Unified Reporting

For performance monitoring and KPI forecasting.

Production Proven

Designed for immediate value creation.

Automated Model Generation

Users can focus on analysis and decision-making while models are automatically generated, calibrated and maintained.

Fully Integrated

One Digital Twin Framework built with independently deployable modules.

Highly Scalable

Seamless deployment and execution across small and large fabs.

AI-Enabled

Interface module to train large AI models.

Products

D-SIMCON

Function

Decision

Time Horizon

Strategic

Tactical

Operational

Day

Week

Month

Year