- Home

- >

- D-SIMCON

- >

- D-SIMCON Static Capacity Engine

D-SIMCON Static Capacity Engine

Advanced Planning Solution for Semiconductor Capacity Planning

CHALLENGES

- Constraint-based production planning (such as simulation) can be very time-consuming.

- Optimised capacity plan needs to be generated with as few iterations as possible.

- Many Semiconductor Manufacturers are still using inhouse developed / Excel-based solutions for production planning.

- Input data changes and scenarios need to be managed consistently, especially when several planners are involved.

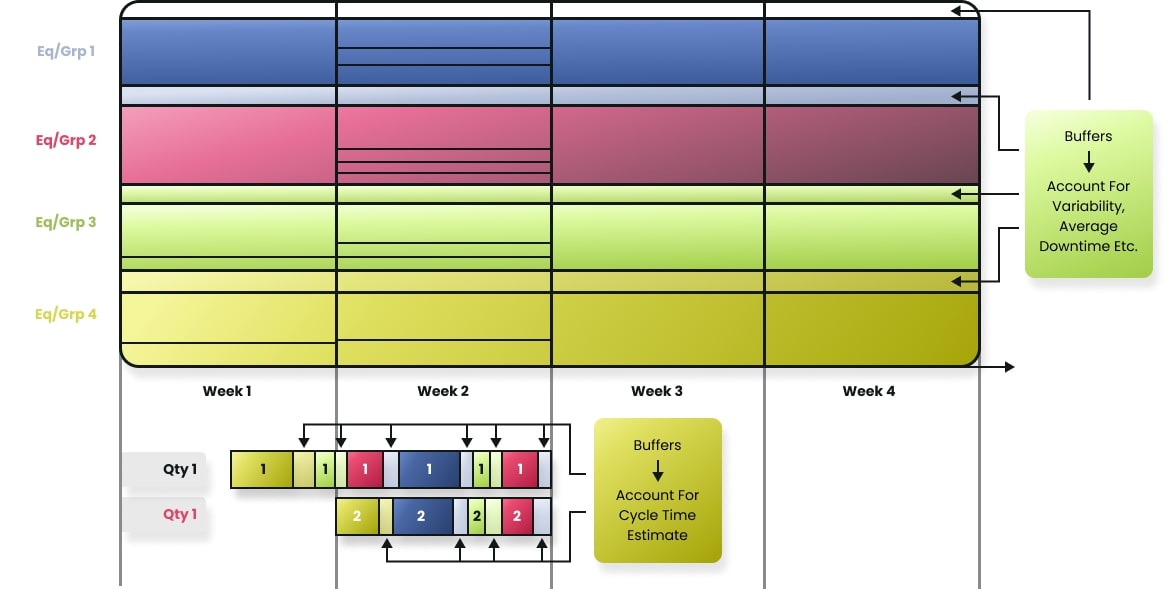

- Production cycle times typically span up to several months.

- Cycle times need to be considered for allocation of production quantities to capacity planning (weekly or monthly) time buckets.

Solution

- D-SIMCON Static Capacity Engine is a comprehensive, easy-to-configure and powerful capacity and production planning solution specifically designed for Semiconductor Manufacturing.

Differentiators

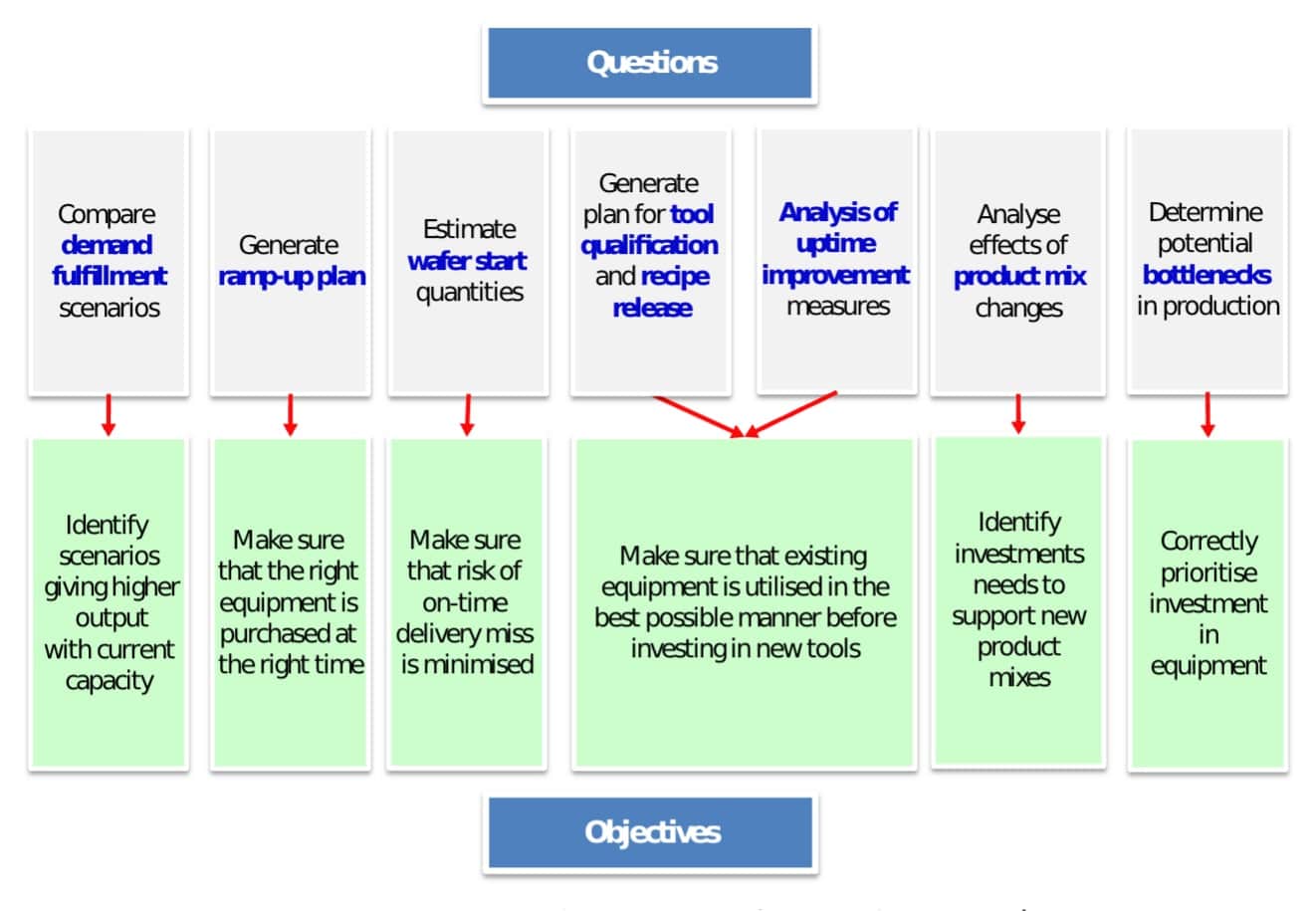

- Use case based approach.

- Wafer fab specific constraints and equipment characteristics can be portrayed.

- Throughput dependency on the combination of products and layers.

- Alternative recipe mapping.

- Route branching with corresponding machine load.

- Details of equipment dedication to recipes, products and steps.

- More automated and systematic way of capacity planning.

- Centralised and standardised input data with automatic base project generation for consistent planning.

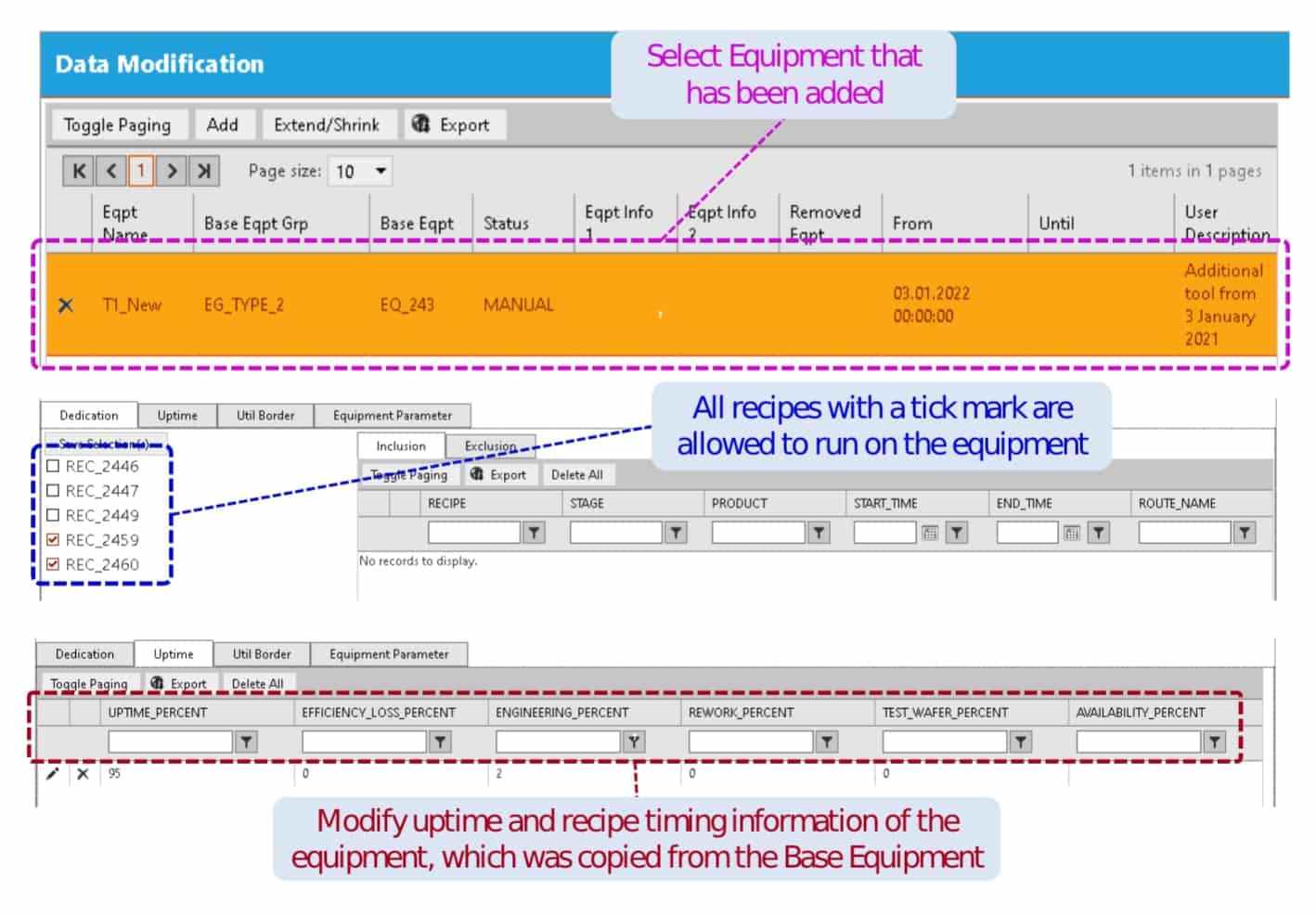

- Quickly adjust input data for what-if scenarios without modifying base data.

- Automatic balancing of product quantity allocations to tools within Equipment Groups.

- Highly scalable for concurrent generation of plans across multiple time buckets on cloud-based or on-premise parallel computing infrastructure.

CUSTOMER SUCCESSES

- Deployed by semiconductor manufacturers in Singapore, Europe, and the USA for both 200mm and 300mm fabs.

- Utilised by customers for sales target setting and capital investment assessment.

Benefits achieved

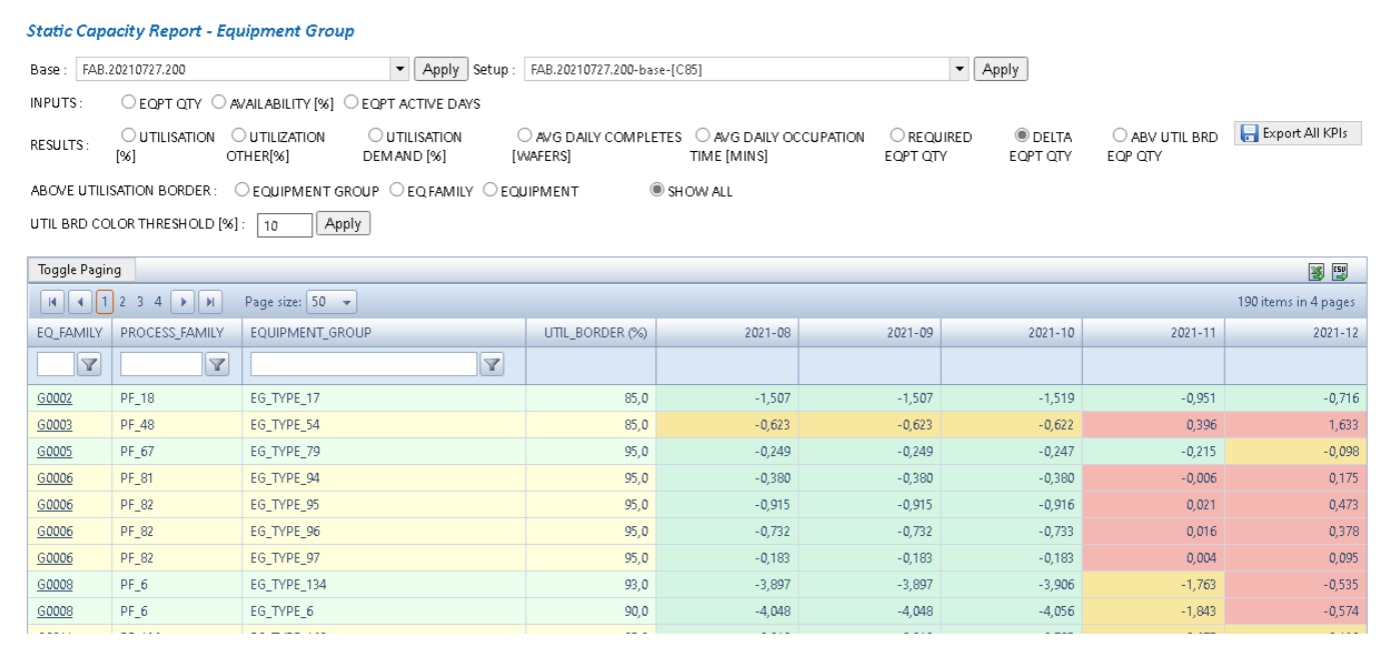

- Up to 5% capacity freed up at critical Equipment Groups.

- More accurate and realistic capacity planning.