Digitalisation is driving increased demand for microchips and shortening the product lifecycle and the high variety of customer specific devices leads to a growing need for high-mix low-volume (HMLV) semiconductor production. As such, factories to make such chips are complex, continuously evolving systems that are never in steady state.

In the light of recent advancements in Artificial Intelligence, there is also huge potential for application of AI techniques in the semiconductor manufacturing industry to further increase the efficiency and performance of factories. Wafer fabrication facilities in particular are producing an enormous amount of data every day, which can be used and are very valuable for the training of AI models. However, just using historical data will result in an AI model to just learn from past patterns and existing logic, so decisions about what to do in future will be biased towards how they have been made in the past, for example through existing dispatch rules. Using a simulation model will allow to significantly supplement the training data set with situations that have not appeared in historical data and allows the AI algorithm to experiment with decisions and their resulting impact which cannot be tested in the real factory. This is particularly important in a fab environment with short product lifecycles requiring frequent change of settings, making it virtually impossible to learn from historical data, especially in the context of capacity optimisation and scheduling.

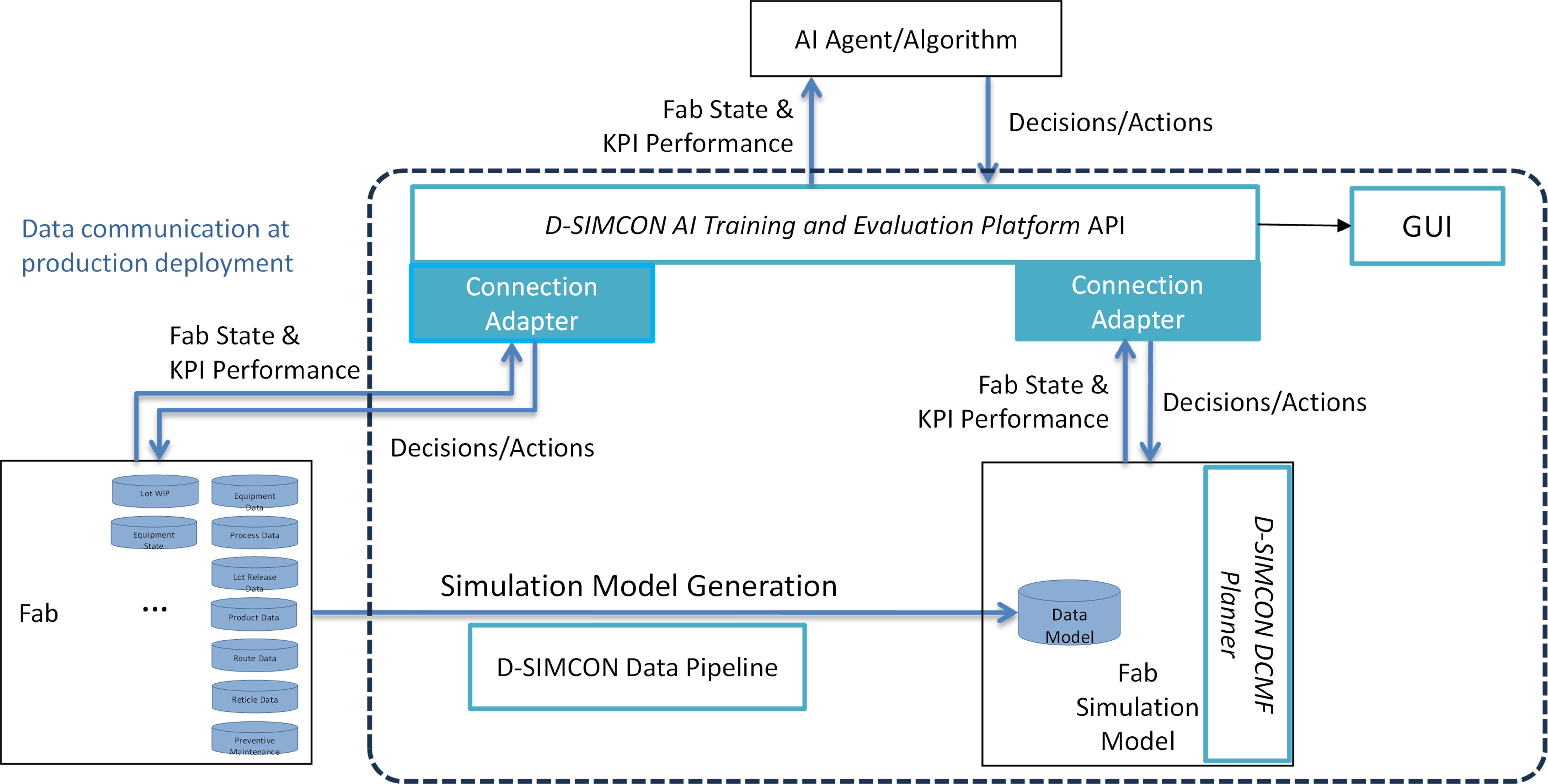

The D-SIMCON AI Training and Evaluation Platform facilitates a tight integration between an AI model and a simulation model through a standardised communication interface which allows fast and efficient training. A Python API is part of the platform, making integration with existing AI modules/libraries an easy task and allowing bi-directional real time communication to

- Retrieve data about the current virtual fab situation,

- Send instructions (i.e. actions to be executed) to the simulator,

- Collect KPI performance results.

The D-SIMCON AI Training and Evaluation Platform was developed by D-SIMLAB within the European funded ‘AISSI – Autonomous Integrated Scheduling for Semiconductor Industry’ consortium to source and develop, integrate and apply novel AI-based approaches for the semiconductor industry.

The platform is powered by the well-established and proven D-SIMCON Dynamic Capacity and Material Flow Performance (DCMF) Planner which is already used by many IDMs, Foundries and Memory Manufacturers across the globe. Simulation models of high accuracy are generated automatically based on fab data.

The trained AI model can be connected to the fab execution system (MES) via the same protocol, as the D-SIMCON AI Training and Evaluation Platform can communicate with any system-compatible with the AISSI platform, This makes it easy to deploy the trained AI model into production.

The D-SIMCON AI Training and Evaluation Platform comes with numerous special features, making it very flexible and scalable:

- Parallel training on multiple compute nodes, on premise or in the cloud.

- Adjustable KPI measurement at different aggregation levels and granularity

- Roll-back of simulation to defined points of time to make the AI training more efficient and allocate runtime to more favourable settings.

- New types of actions / decision variables can be added.

A first case study showcasing the power of this platform to train a situation-based Reinforcement Learning enabled dispatch agent was presented at the Modeling and Analysis of Semiconductor Manufacturing (MASM 2023) Conference in San Antonio TX (USA) on 13 December 2023. A Deep Reinforcement Learning enabled dispatch agent was trained and tested using the D-SIMCON AI Training and Evaluation Platform incorporating a simulation model of one of the Infineon 200mm wafer fabs. It is the first application of Reinforcement Learning to a real-world, large-scale fab. For unseen test scenarios, a single digit percentage flow factor improvement as well as a constant two-digit percentage reduction of fab out due date violation was observed.

This case study will again be featured at the Q1/2024 meeting of the SEMI Fab Owners Alliance in Phoenix AZ (USA) on 25 January 2024.

For further details please contact:

Dr Peter Lendermann, Chief Business Development Officer, peter@d-simlab.com